Skip to main content Creating Setup

- Switch from “Design” to “Manufacturing” workspace in Fusion (top left corner)

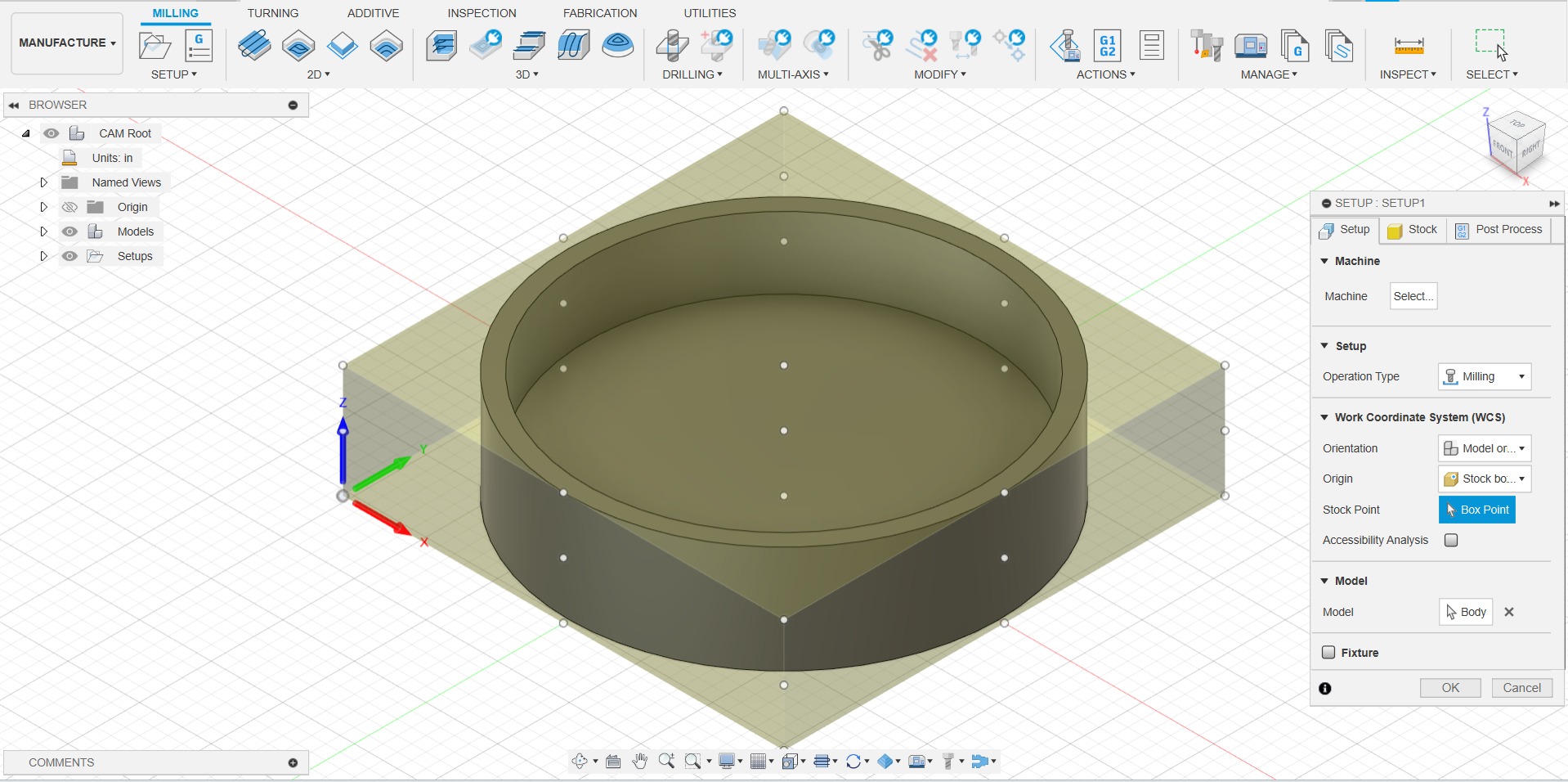

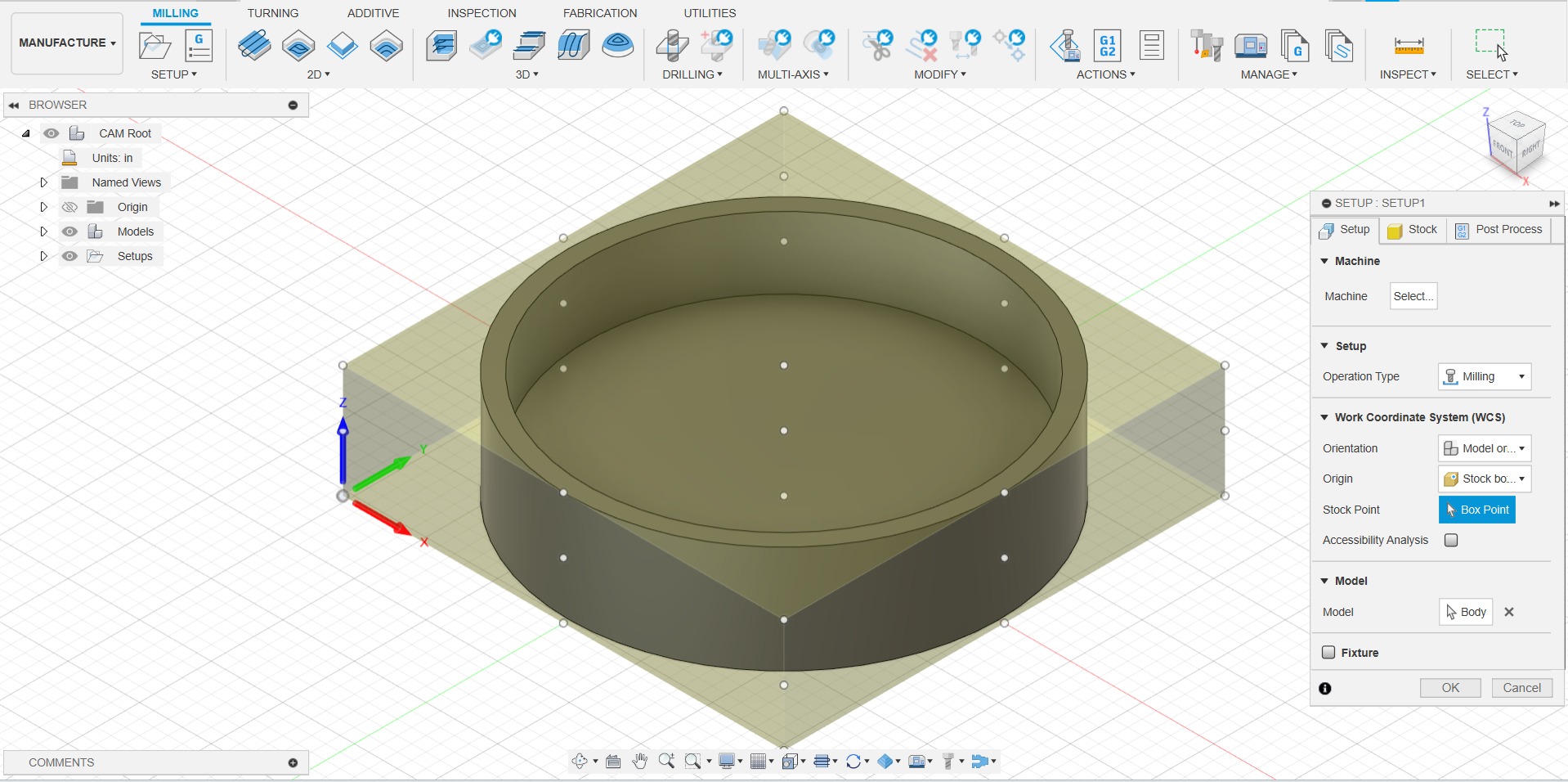

- Setup > New Setup

- On “Setup” tab, set “Stock Point” to the BOTTOM corner of the stock

- Previous instructions used top of stock & update bit length, this approach is not compatible with multi bit operations

- Still in “Setup” tab, select the model body/bodies to be machined

- In the “Stock” tab”, select “Fixed Size Box” (preferred) or “Relative Size Box” (advanced)

- Set stock dimensions to actual measured values

- Use calipers to measure stock thicknesses, inaccurate values can result in broken bits

- X,Y dimensions are important but not as critical as material thickness (Z).

- If the model orientation doesn’t fit within the specified stock, use a “Manufacturing Model” to rotate or re-arrange parts to fit.