Skip to main content Procedures

Startup Procedure

- Turn on air pressure using Air Inlet

- Verify pressure on Pressure Regulator is approximately 0.45 MPa

- Turn on power using the Power Switch on the control box

- Switch key to “ON” (clockwise)

- Press green power button

- Wait for system to boot

Shutdown Procedure

- Park any installed tooling (Home screen > Park)

- Press green power button

- Switch key to ‘OFF’ position (counter-clockwise)

- Turn off main power

- Turn off air

Running Program

- Insert USB device into the control panel

- Copy project file from USB

- From the control screen

- Setup > Program Manager

- Select “USB” tab on left

- Select desired file (.PRG extension)

- Can sort by name, date, size

- With file selected, press “Copy”

- Select “Programs” tab on left

- Select “Paste”

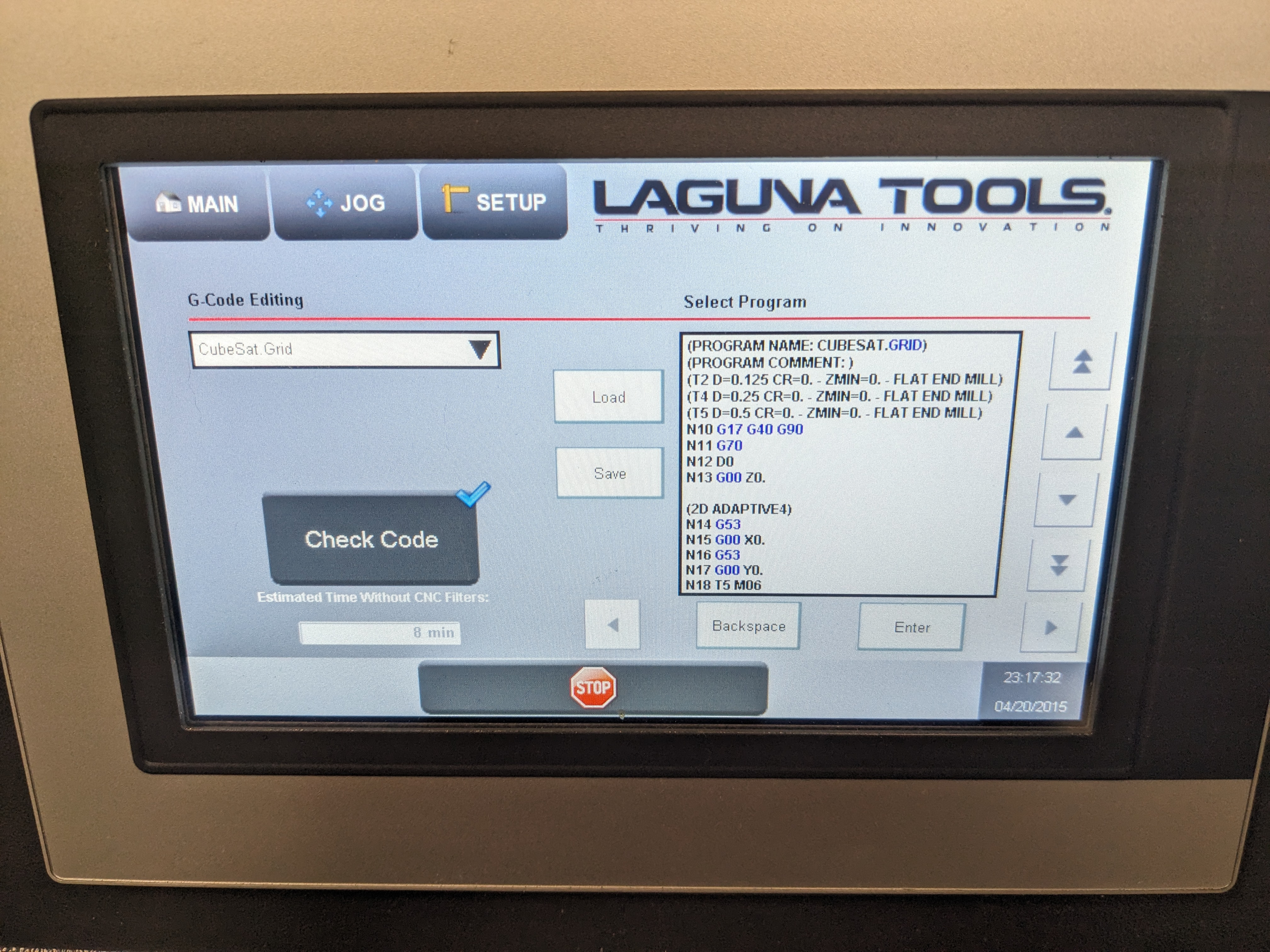

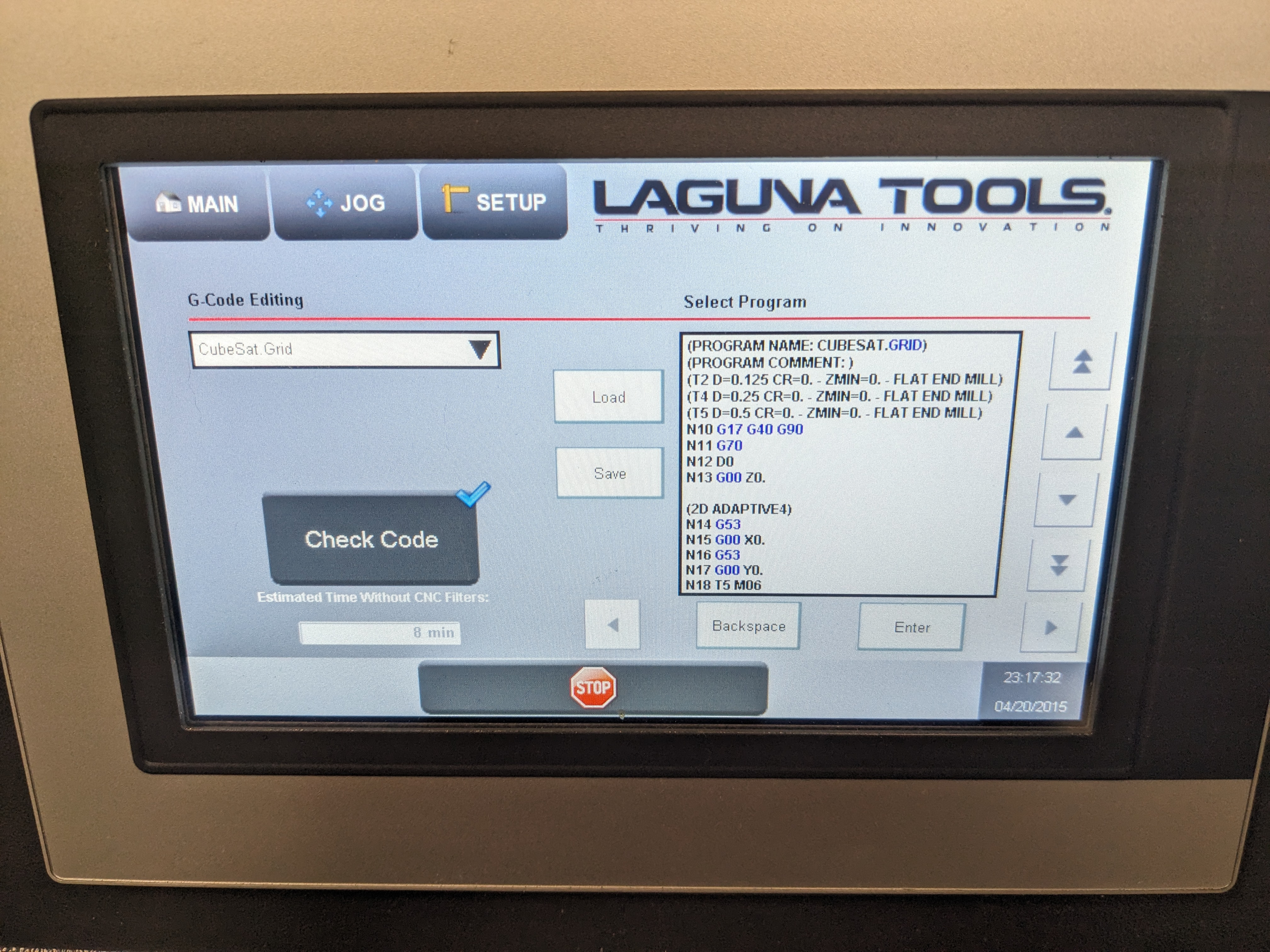

- Verify GCode

- From control screen

- Setup > Verify G-Code

- If program not already select use drop down to select

- Select “Load”

- Select “Check Code”

- Wait for check to complete, indicated by a blue check mark or a reported error

- Load a tool into the toolhead (if not already loaded)

- Option 1 - Auto Touchoff (Recommended)

- Setup > CNC Tool Data

- Select tool number from dropdown

- Select “Execute Automatic Touch On/Off”

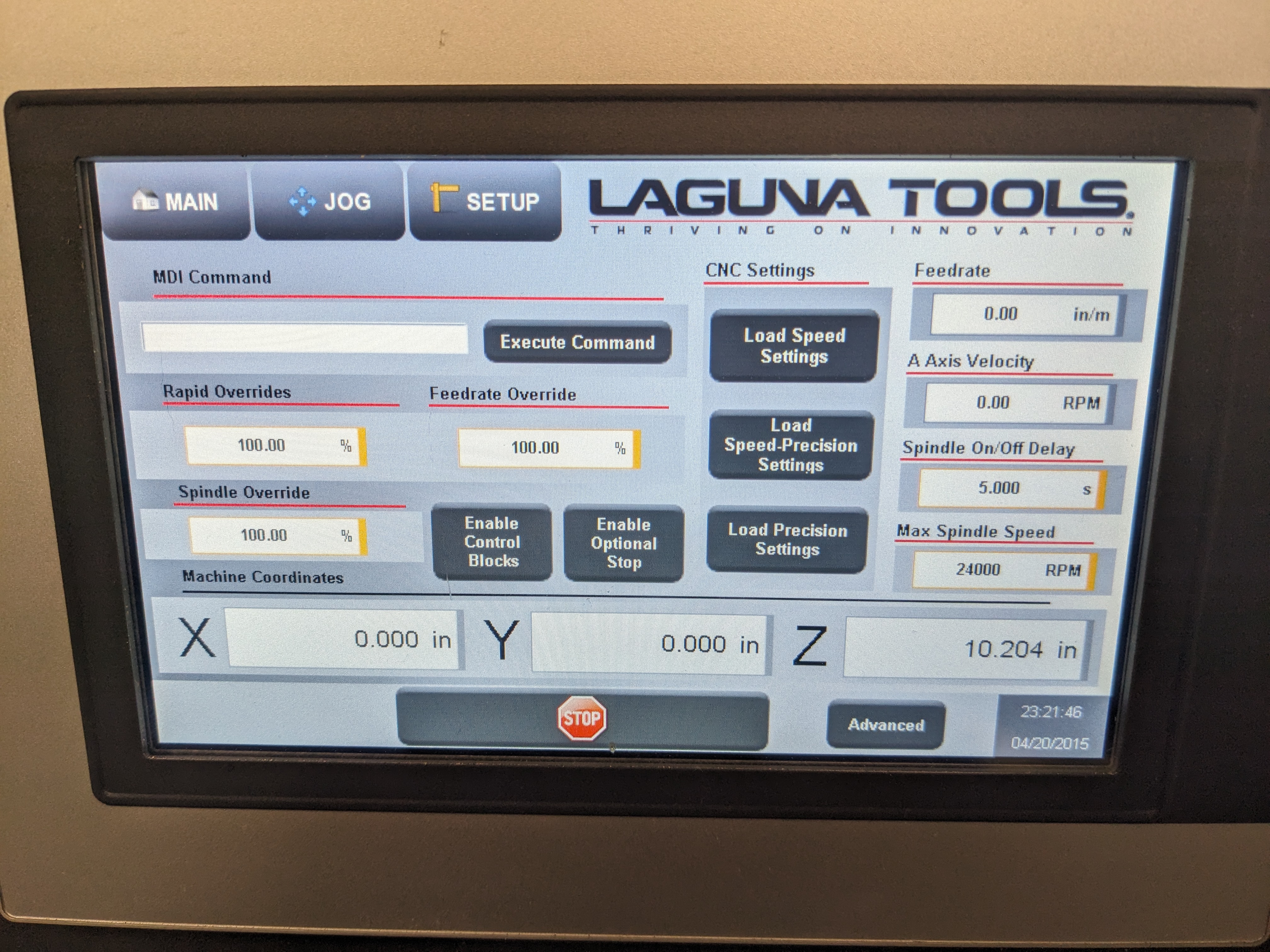

- Option 2 - MDI Command (Advanced)

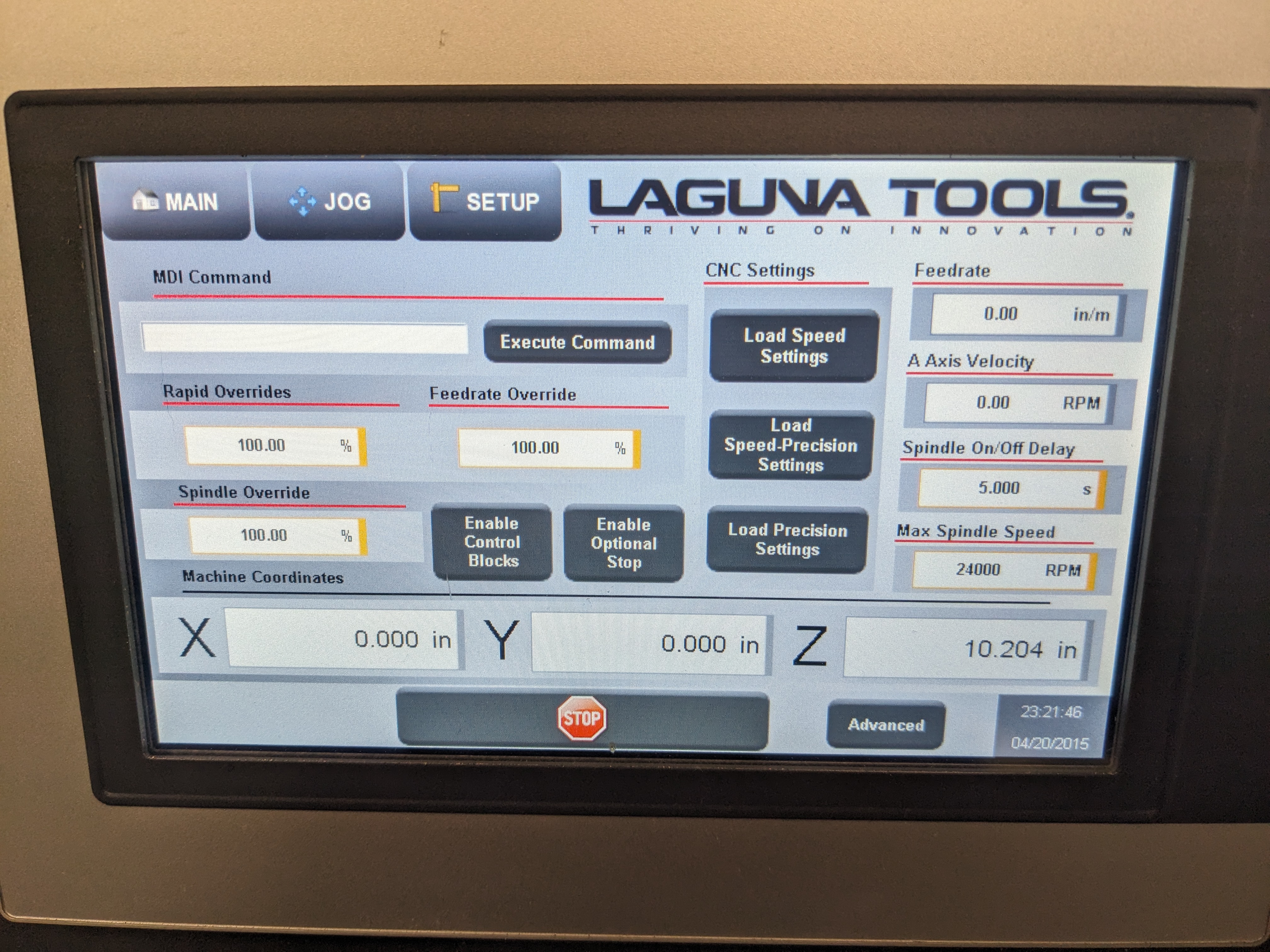

- Setup > CNC Settings

- MDI Command

- “M06 T<tool number>” e.g.

M06 T2 // load tool #2

- Position the toolhead at the X,Y origin of the stock

- Use the handheld remote to manually jog the toolhead

- Press and hold the “Enable Switch” on the remote to allow motion

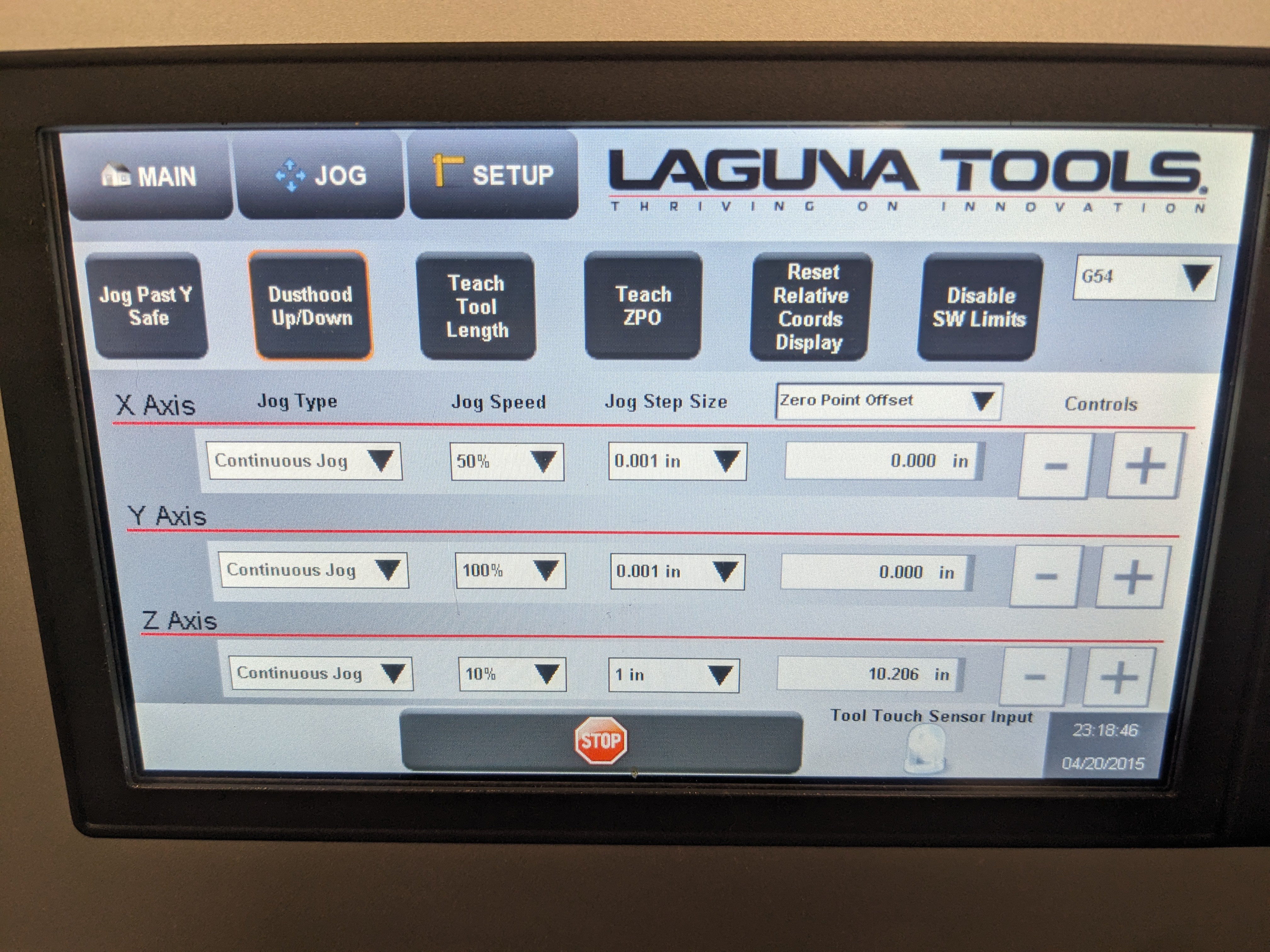

- Will automatically open the “JOG” screen

- Select movement axis using left dial (X,Y,Z,4)

- Mill does not currently have a 4th axis

- Select the movement multiplier using the right dial (1x,10x,100x)

- Avoid using the 100x multiplier when moving the Z axis, it could result in bit breakage

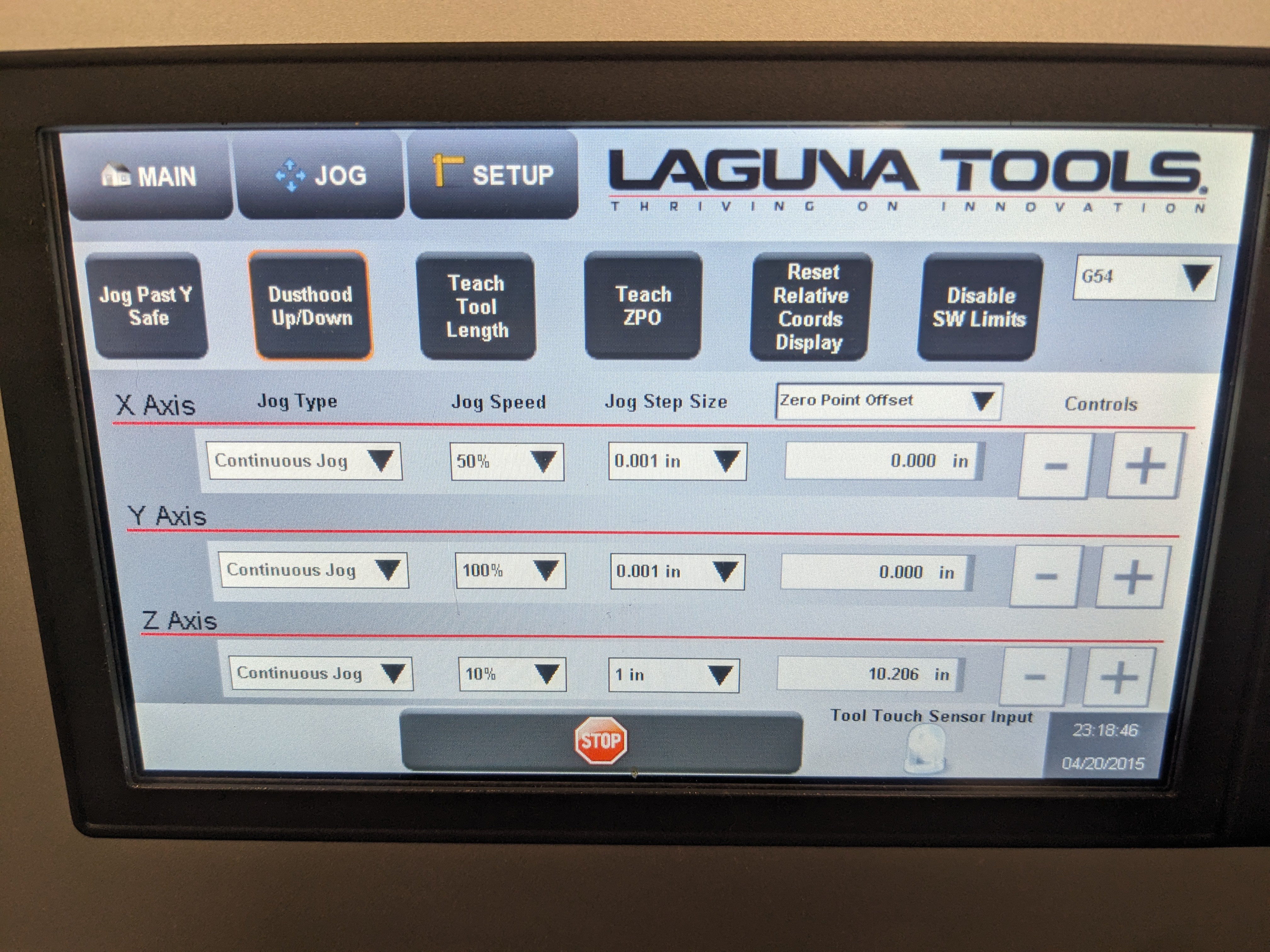

- With bit position over the X,Y origin of the stock, press “Teach ZPO”

- The dust boot can be raised on the Laguna control screen to provide a clear view of bit during alignment

- DO NOT PRESS “Teach Tool Length”, tools should only be zero’d using the auto touch off system

- Verify X,Y origin was set correctly

- With “Zero Point Offset” selected from the drop down (not Machine Coordinates or Relative Coordinates), verify X Axis and Y Axis read <= 0.001 in

Pausing a Program

- To pause operation, press “Hold” from main screen

- Spindle remains ON by default when paused

- Spindle can be stopped (optionally) via

- Main > Settings

- Set “Spindle Override” to 0%

Resuming a Program

- If spindle was turned off, (0%), set “Spindle Override” to 100%

- DO NOT resume cut operation with spindle at 0%, this could damage bits or the machine

- From “Main” tab, press “Run”

Emergency Stop

- The emergency stop buttons on the Control Box or Remote can be pressed at any time to immediately stop all machining.

- Program stopped via E-Stop cannot be resumed (i.e. E-Stop is not a pause)